HVAC PERFORMANCE TESTING

HVAC Performance Testing measures how efficiently your system is running, where system problems exist, and thus where to make improvements to maximize efficiency.

Close to 50% of the electricity you buy is for heating and cooling, so better HVAC performance saves lots of money and makes equipment last longer. The national average for HVAC performance is a dismal 57% of your system's rated capacity

[Source: National Comfort Institute]

PROCESS

Since air conditioners are the largest consumers of electricity in most hot, humid climates, energy efficiency requires that ...

1) A/C units perform close to their design capacity when cooling the air (system performance)

2) Very little of this cool air leaks into attics and other place where it is wasted (system tightness)

3) Cool air is distributed in the proper amount to every room (system balance)

These variables can be tested scientifically and the A/C system optimized with the data gathered. It is often possible to gain more performance from your existing unit by optimizing it than from buying new equipment - at a small fraction of the cost.

Most air conditioning contractors do not have the knowledge, equipment, or motivation to optimize systems, as they make more money simply replacing equipment. Perhaps this is why the national performance average for these systems is 57% of rated capacity (data from over 20 years of testing by the National Comfort Institute).

Here are the diagnostic tests for diagnosing performance:

System Performance

-

System Temperature Change

This test measures the temperature of air entering your system at the return grill and compares it to the temperature delivered to the supply registers in your ceilings. This shows the actual

temperature change your system is delivering.

-

Air Flow

This measures the volume of air flowing into each room and total system flow.

-

Delivered BTU

The purpose of an air conditioning/heating system is to remove/add heat to the air passing through

it and deliver this "conditioned" air to your rooms. The Btu your system is removing/delivering is

simply a function of how much your system changes the air temperature and how much of this

conditioned air is delivered. [12,000 Btu is 1 “ton”]

We calculate your system’s Delivered Btu with the data collected (above) about delivered air volume

and system temperature change.

-

System Efficiency

This is a comparison of how many Btu your system is delivering to how many it is rated to deliver.

The national average is 57%. The goal should be over 90%.

If performance is less than 90% of rated capacity, these further tests uncover where the problem lies.

-

Equipment Temperature Change

This measures how much heat is being taken out of the air as it passes through the air

conditioning equipment. Comparing equipment temperature change to entire system

temperature change reveals ...

- how much heat is being lost or gained in the duct system

- if the HVAC equipment is producing adequate temperature change

-

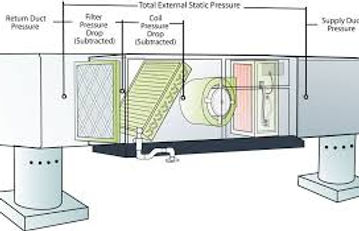

External Static Pressure

This is the pressure in your A/C system that your fan must push against. If it is higher

that what the fan is designed for, the volume of air distributed to your rooms can

decrease dramatically.

-

Filter Pressure Drop

This test measures how much your air filter is restricting air flow and reveals if you need

a better approach to filtration or a larger area of air return grill.

-

Evaporator Coil Pressure Drop

This tests the difference in pressure on either side of the evaporator coil. It shows how much

the coil is restricting air flow and whether it needs cleaning.

-

Borescope Examination

A small camera is inserted into the equipment to literally see the condition of the

evaporator coil or other components of the A/C system.

System Tightness

-

Duct Leakage Tests

These tests measure the volume of air, in cubic feet per minute, leaking from the

distribution system. Tests for both total duct leakage and duct leakage to outside

the conditioned space can be performed.

-

Pressure Pan Test

This test is run in conjunction with a blower door test to reveal which supply duct runs and return air channels have major leaks.

-

Smoke Machine Test

This test, used in conjunction with duct blaster equipment, gives visual evidence of where duct

leakage is occurring. It is particularly valuable in spotting leakage points in hard-piped ducts covered up by insulation.

System Balance

-

Air Balancing Test

Air Balancing is the process of measuring and adjusting the volume of conditioned

air flowing into each room to ensure the room is comfortable. Usually the process

begins with a calculation of how much air should be supplied (a Manual J room-to-room

heat load calculation). Then the volume of air actually entering each room is

measured in cubic feet per minute with an Air Flow Hood. Finally, airflow to

each room in your house is adjusted to "balance" the house.

This is the gold standard for testing air conditioning system efficiency. And since

A/C efficiency is a prime determinate of overall home energy efficiency in hot, humid

climates, these system performance tests provide the data needed to increase your

home’s actual (as opposed to theoretical) efficiency.